A third generation Calexican, Chris was gifted his grandparents home. This property was the result of his grandparents and great grandmother toiling under the sun in the fields of Imperial Valley as farm workers. Through their hard work and dedication enough money was saved to purchase a piece of the American dream for this immigrants.

Changing state laws allowed for Accessory Dwelling Units (ADU) also known as granny flats to be built on site. Building on what his grand parents had done it was decided to create a new ADU in the backyard.

Seeing the effect of climate change in the low desert of Southeastern California – longer summers and higher nighttime temperatures there was a need to choose a building material that is both resilient, carbon negative and a good insulator. Temperatures can reach as high as 120 degrees during the summer and the upper 20s during the winter. High humidity and temperatures are common in the late summer as the Southwestern monsoons bring moisture from Mexico. Temperatures can also fluctuate 30 degrees between night and day throughout the year.

The question was how to built using passive technology while retrofitting the future unit against the extremes of climate change. Many different materials were researched and ultimate Hempcrete was chosen. Hempcrete is versatile in the sense that it regulates both humidity and temperature while being carbon negative and continues to sequester carbon throughout the life of the building.

The first builder was detailed, understood the materials and was keen properly mixing and casting the western wall and two interior walls. A pause was needed due to funding constraints and when additional funding was secured the original builder had secured their work and was unable to continue the project.

A second builder approached the project as an industry expert. To the untrained eye they had experience with their website being full of small Hempcrete based projects. This second builder promised impeccable work and an ambitious timeline which was important because ideal casting of Hempcrete should take place when temperatures are between 40f-90f. The climate of the low desert exceeds the upper threshold beginning in mid to late April.

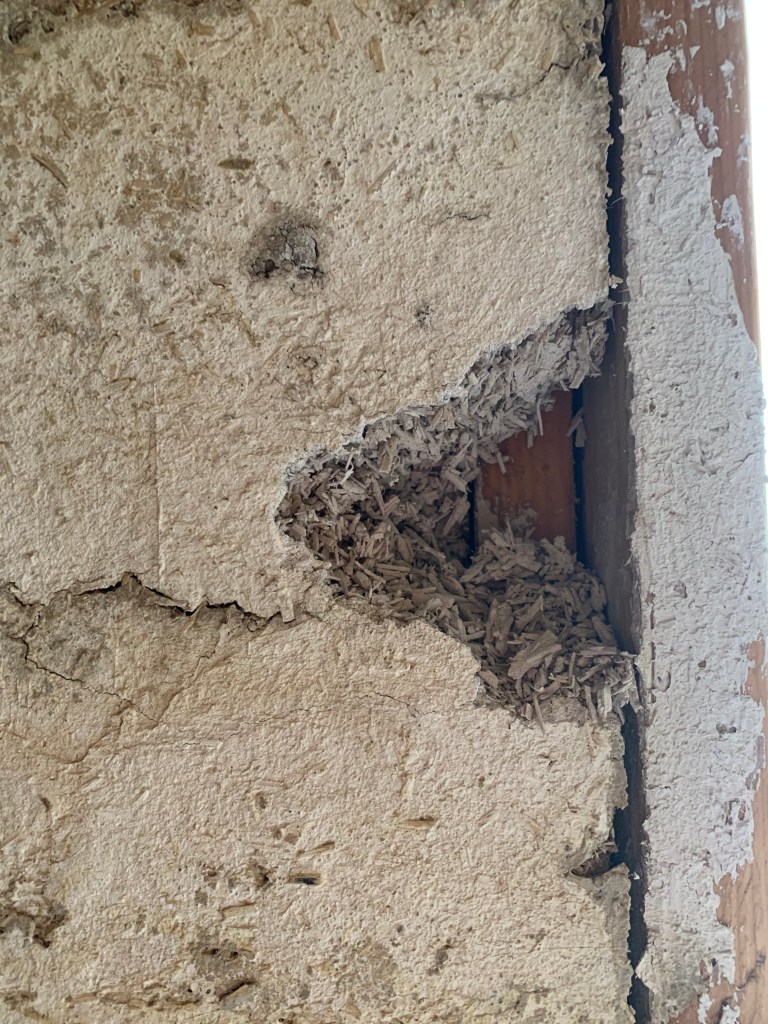

What resulted from this second “expert builder” was, improper mixing, use of standard Type S lime, and poor craftsmanship lead to the three remaining walls being unstable, showing cracks and beginning to fail, meaning they are substandard and will not pass inspection from the local government. In short, the second builder grossly misrepresented their capabilities. This “builder” has since been let go, however, funds were not returned and the project has been paused. Additional funding is needed to carefully take down the three walls the second builder placed and rebuild them with an experienced mindful Contractor.

Chris’ story in Hemp builders magazine!

Take a look for yourself: